Georgsmarienhütte, 12 February 2024

Simulation at GMH: Reducing CO2 emissions through process optimisation

Software and model-based simulation makes a significant contribution to reducing CO2 emissions resulting from reduced consumption of electricity and coal in GMH Gruppe’s steel production.

The digital simulation of production processes is one of the key factors in achieving GMH Gruppe’s goal of complete decarbonisation by 2039. A pioneer among medium-sized companies in setting up its own simulation department, GMH is already benefiting from significant savings. Through simulation, GMH has been able to make its processes more efficient, thereby reducing CO2 emissions and lowering the consumption of primary and secondary energy such as electricity and coal.

Fewer emissions through simulation

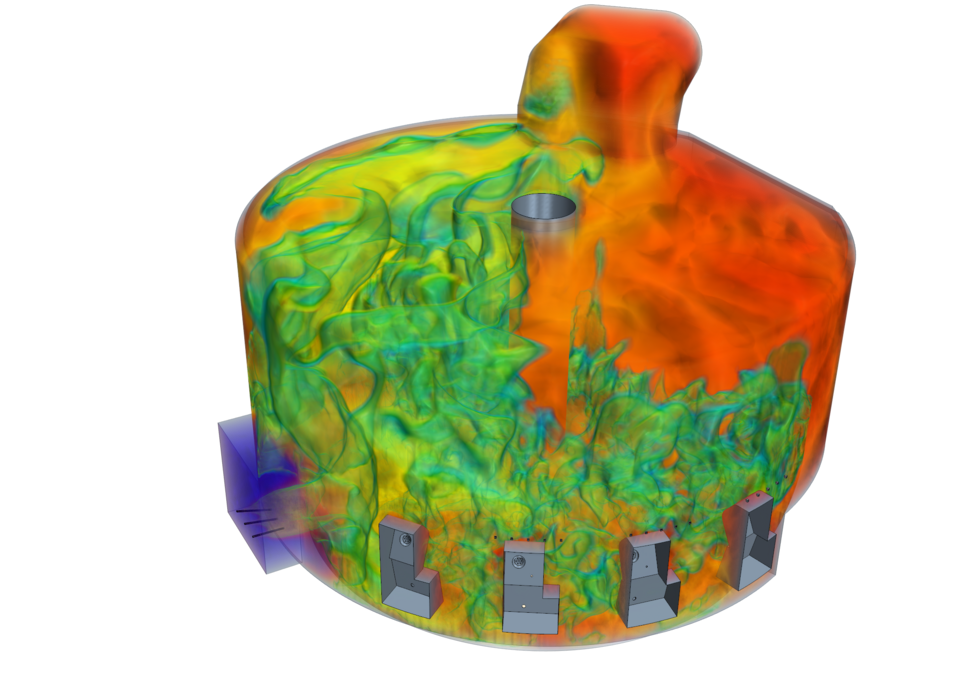

A metallurgy expert’s dissertation provided the impetus for the targeted testing of new coal-supply schemes for production processes in Georgsmarienhütte’s electric-arc furnace. As a pioneer of sustainable steel production, the company had already introduced this production method, instead of the conventional blast furnace, a good 30 years ago. To this end, the experts in the simulation team worked closely with the production department to evaluate data from historical production batches using machine learning methods – and thus generated valuable forecasts for future optimised production process options. This allowed new schemes to be defined and confirmed in just a few production trials.

The validated results set the standard for more energy-efficient and therefore more environmentally friendly steel production at GMH. Significant savings in steel production are now being realised with the new processes: Ten kilowatt hours less melting current is now consumed per tonne of liquid steel and around five kilograms less coal. These optimisations alone reduce CO2 emissions by 14.7 kilograms per tonne of liquid steel produced.

“With projects like this, we are setting the course for the future in order to position GMH today in such a way that we will still be competitive in 20 years’ time. Digital transformation plays a central role in this. We were one of the first medium-sized steelworks to recognise this and will continue along this path step-by-step,” says Dr Alexander Becker, CEO of GMH Gruppe.

Follow-up projects for long-term competitiveness

This is all the more true, as the experience gained from this project will be utilised for the switch to biogenic coal. In the current year, GMH aims to achieve the target of producing 60,000 tonnes of its CO2-reduced quality “Green Power Premium” steel. The use of biogenic coal plays a decisive role for GMH Gruppe. In combination with the use of renewable energies for the operation of the electric-arc furnaces, GMH can reduce CO2 emissions to just 0.05 tonnes of CO2 per tonne of steel produced – compared to around two tonnes with the conventional blast-furnace route.

Precise predictions are crucial

However, the department does not just specialise in coal supply or furnace operation. In its projects, it covers the entire spectrum of steel production and processing, such as the simulation of flows, solidification, forming, thermodynamics as well as the logistical material flow and chemical processes.

Energy-intensive processes, such as casting in all its various forms, as well as rolling and forging, offer the greatest leverage for savings. The major challenge is that a truly effective simulation must be very precise, so that only a few practical test sequences are required during regular operation of the systems to achieve the desired result.

A strong team with competent partners

The whole thing only works with strong partners – both internal and external. The members of the simulation team complement each other with their different skills at the interface between engineering knowledge, expertise in materials and production processes. It is an international melting pot of expertise from metallurgy, fluid mechanics and forming to process engineering. The only thing that matters is expertise and the ability to work together. In its projects, the team is always in close dialogue with the actual steel production. GMH also relies on external partners such as specialised software solutions and hardware specialists, who deliver high-performance infrastructures.

About GMH Gruppe

GMH Gruppe is a full-range supplier of recycled input material through ready-to-install components and one of the largest privately owned metalworking companies in Europe. The group comprises 15 medium-sized production companies in the steel, forging and casting industry and is present in more than 50 countries. With around 6,000 employees, the GMH Gruppe generated annual sales of around two billion euros in 2021. GMH Gruppe is a pioneer in sustainable steel production and has also been accepted into the “Association of Climate Protection Companies”. By recycling scrap metal, the company produces Green steel and thus makes an important contribution to the circular economy. The use of electric arc furnaces at four of its sites reduces carbon dioxide emissions by a factor of five compared with conventional blast furnaces. This, in turn, also reduces the carbon footprint of GMH’s customers. Global customers include companies from the automotive industry, mechanical and plant engineering, railroad technology, power generation, transport logistics as well as the sectors, aerospace, agriculture and construction machinery. The GMH Gruppe has set itself the goal of being completely climate-neutral by 2039.

About Georgsmarienhütte

Georgsmarienhütte GmbH, based in Georgsmarienhütte, Lower Saxony, is a leading European supplier of crude steel, steel bars and bright bars based on quality and engineering steels. In addition, the company supplies machined and ready-to-install components. Already today, Georgsmarienhütte is one of the most climate-friendly steel companies in Germany. With its comparatively low-CO2 value chain, which consists of melting scrap in the electric arc furnace and recycling it into new steel, the company is a pioneer in sustainable steel production, making an important contribution to the circular economy. The methodology used by Georgsmarienhütte to calculate its Product Carbon Footprint (PCF) has been validated by TÜV SÜD and is now being applied to more than a thousand steel variants. Besides the automotive industry and its suppliers, Georgsmarienhütte serves customers in the mechanical and plant engineering and energy industry. Steel made in Georgsmarienhütte is used where exceptional stresses have to be coped with, where power is generated and immense forces have to be transmitted, and where safe and wear-resistant operation is essential.

More information is available at www.gmh.de.

For inquiries

bmb-consult – PR-Agentur der GMH Gruppe

Simone Boehringer

Senior Editor & Senior Account Manager