Hydrogen Technology Offensive

Technology experts of GMH Gruppe work with partners in a joint research project aimed at reducing the carbon footprint of secondary steel production by means of a new burner concept and future use of hydrogen to replace fossil fuels in steel melting. The hydrogen technology offensive started as early as last year with the OptiLBO project.

Steel is one of the most important materials in industrial sectors such as construction, mobility and mechanical engineering. Steel production is very energy-intensive and it is in the nature of the steelmaking process that it produces large amounts of CO2. However, there is great potential for reducing the carbon footprint both in primary and secondary steelmaking.

Energy-efficient steel production and reduction of CO2 emissions

OptiLBO is the name of a research project that provides the framework for GMH Gruppe and its partners – Gas and Heating Institute Essen and the companies Kueppers Solutions and Küttner Automation – to explore the possibilities of making secondary steelmaking significantly more efficient and sustainable. Some 12 million t of secondary steel are produced in Germany every year. Reducing the amount of energy necessary to produce this quantity of steel by 20 percent would save some 120 GWh of energy and 20,700 t of CO2. This equates to the amount of energy consumed by more than 4,000 average single-family homes.

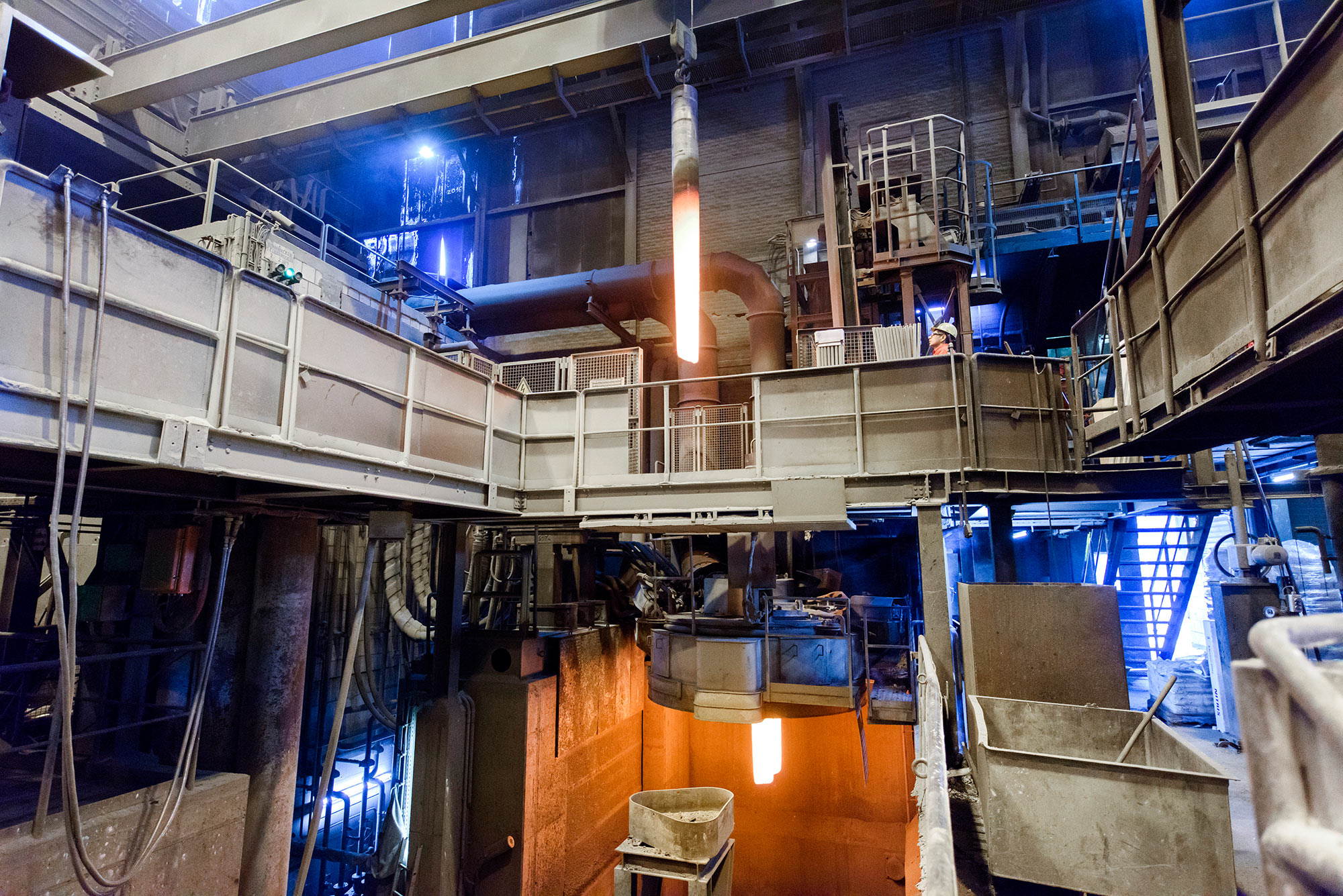

To this purpose, the research team in the OptiLBO project is examining steel production in the electric arc furnace of the Bous steel plant in the German state of Saarland. Innovative burners and smart control features are to be used here to reduce natural gas consumption by up to 25 percent. The researchers have calculated that this enhanced technology could save some 5 GWh of energy and almost 900 t of CO2.

In addition to innovative burner technology and self-learning process control systems, the OptiLBO researchers pursue a third target: Introducing hydrogen as fuel with the aim to almost completely replace natural gas.

Steelmaking in the electric arc furnace (EAF): Graphite electrodes generate a high-temperature electric arc that melts the steel scrap in the furnace hearth.

Optimal pre-mixing of combustion gasses and digitalized process control

In the EAF, fuel gas and oxygen are mixed directly in the combustion chamber. With burners of current design, gas mixing is not controlled and, therefore, the mixture is not always optimal for the furnace’s specific operating state. In the extreme, the natural gas has already reached the exhaust gas system when it combusts, meaning that the combustion heat is not transferred into the steel bath.

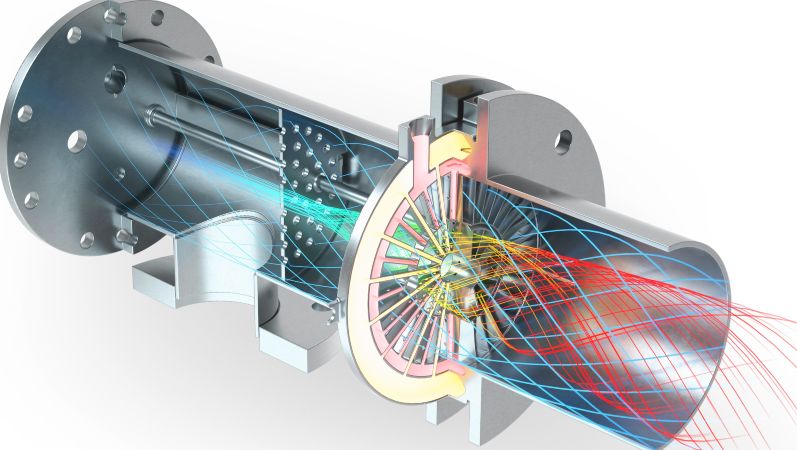

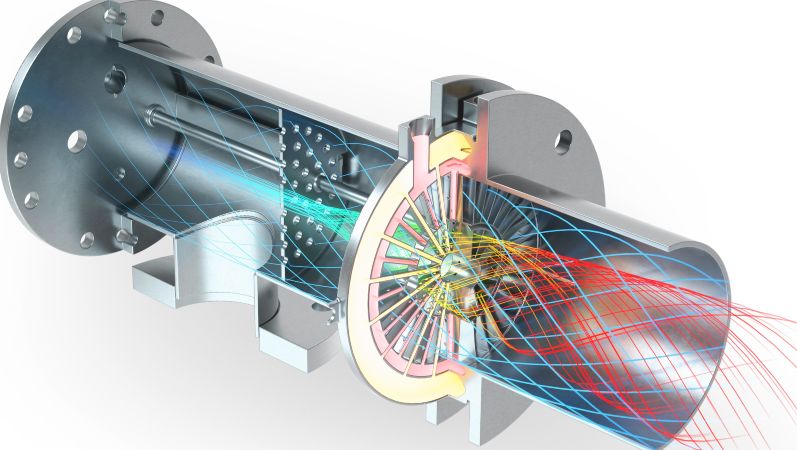

To solve this problem, the OptiLBO team is developing an innovative burner that comes with an additively manufactured mixing device. This device achieves quicker and, above all, more effective mixing, ensuring complete combustion of the gas mixture and maximized heat transfer into the steel bath. In addition to this, NOx emissions are about 90 percent lower than with industrial burners of conventional design.

The new, innovative burners operate in combination with a self-learning control system that is based on different simulation models and uses artificial intelligence. The system recognizes the process state, provides data for process forecasts and controls the melting process in such a way that only the heat input necessary at any specific time has to be added. Thus, scrap melting in the electric arc furnace becomes more energy-efficient, while releasing less CO2.

When fuel gas and oxygen are optimally mixed, they combust completely, transferring more energy into the steel bath. (Source: Kueppers Solutions GmbH)

Hydrogen use in steel production to replace natural gas

OptiLBO is the first research project under the Hydrogen Technology Offensive launched by the German Federal Ministry for Economic Affairs and Energy. With the national hydrogen strategy, of which the Hydrogen Technology Offensive forms a part, the German Federal Government aims to promote the use of hydrogen as a regenerative energy carrier.

Research teams analyze how hydrogen used as fuel gas – both as admixture and in pure form – impacts on the steel melting process. An important issue to be examined is if and how hydrogen changes the properties of the hearth material. Furthermore, the researchers analyze the specifics of hydrogen combustion, its heat transfer properties and what kind of pollutants may arise in what quantities.

Examining if and how hydrogen changes the conditions in the hearth of the EAF in Bous is one of the OptiLBO research tasks.

Did you know that …

- for each ton of crude steel produced in the electric arc furnace, the Bous steel mill requires 800 kWh of energy.