Open-die forgings

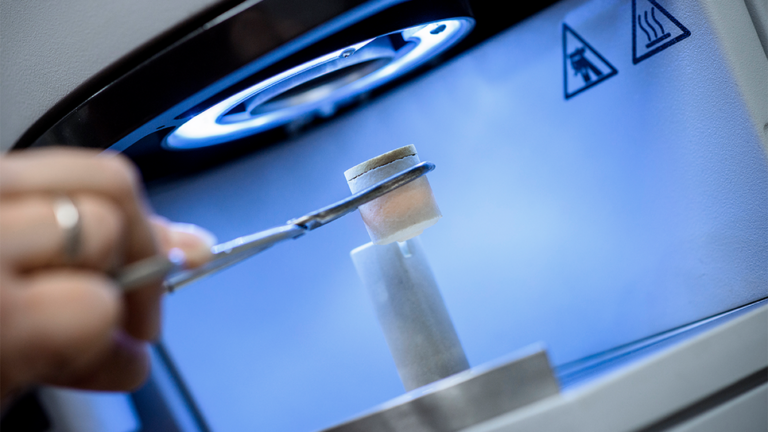

Our open-die forgings are manufactured by forming high-quality steel. In this process, pre-material produced by ingot casting is precisely formed into the desired shape using presses, saddles and dies.

Our ingot steel, which is characterized by special properties such as high degrees of purity, homogeneous microstructure or resistance to wear and corrosion, is used to produce a blank by upsetting, stretching and further forming steps. In order to produce open-die forgings for particularly demanding applications, we have high-performance 27-MN and 60-MN open-die forging presses at our disposal. For complex contours, the material is reheated between the individual process steps. Afterwards, various further processing options are available.

Our portfolio

Shaft-type components

Round forgings with diameters up to 2,000 mm and lengths up to 9,500 mm.

Application examples:

Shafts for power generation and general mechanical and plant engineering

Samples from our Portfolio

Product designation

Steam-turbine shafts

Application

Machine components for the energy sector

Component weight

max. 30 t

Grades

1.6946, 1.6945, 1.6957, 1.4902, 1.4906, 1.4996, 1.4923

Product designation

Modules

Application

Machine components for the energy sector

Component weight

max. 30 t

Grades

1.6946, 1.6945, 1.6957, 1.4902, 1.4906

Product designation

Generator shafts

Application

Machine components for the energy sector

Component weight

max. 40 t

Grades

1.6957, 1.6948

Product designation

Intermediate shafts

Application

Machine components for the energy sector

Component weight

max. 10 t

Grades

1.6957, 1.6948

Product designation

Rolls

Application

Mechanical and plant engineering

Component weight

max. 40 t

Grades

1.2360, 1.2344, 1.2343, 1.6580, 1.6782, 1.7228

Product designation

Compressor shafts

Application

Compressors

Component weight

max. 40 t

Grades

1.6948, 16580

Product designation

Wheel/Gearwheel shafts

Application

Mechanical and plant engineering

Component weight

on request

Grades

1.6587, 1.6580, 1.7225

Product designation

Customised shaft-type components

Application

Component weight

Grades

Your contact for shaft-type components

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Il-Kyu Lee

Sales Director Open Die Forgings & Machining

Disc-type components

Round forgings with diameters up to 4,000 mm and thicknesses up to 1,500 mm.

Application examples:

Washers for power generation, tank construction and general mechanical and plant engineering

Samples from our Portfolio

Product designation

Modules

Application

Machine components for the energy sector

Component weight

max. 30 t

Grades

1.6946, 1.6957, 1.4906

Product designation

Turbine discs

Application

Machine components for the energy sector

Component weight

on request

Grades

1.6957, 1.4906, 1.4996

Product designation

Compressor discs

Application

Machine components for the energy sector

Component weight

on request

Grades

1.6948, 1.6957, 1.4906

Product designation

Impeller wheels

Application

Compressors

Component weight

on request

Grades

1.4313, 1.4418

Product designation

Blade wheels

Application

Machine components for the energy sector/hydropower

Component weight

max. 45t

Grades

1.4313, 1.4418

Product designation

Impeller wheels/Runners

Application

Mechanical and plant engineering

Component weight

on request

Grades

1.6587, 1.6580, 1.7225

Product designation

Primary/Secondary closure heads

Application

Pressure vessels/Nuclear waste disposal

Component weight

on request

Grades

1.4313

Product designation

Vessel heads/bottoms

Application

Pressure vessels

Component weight

on request

Grades

1.4462, 1.4541, 1.4301

Product designation

Customised disc-type components

Application

Component weight

Grades

Your contact for disc-type components

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Andreas Bruntsch

Sales Director Open Die Forgings & Machining

Components for special applications

Forged parts for pumps/valves/fittings

Application examples:

Forged parts for pumps/valves/fittings.

Samples from our Portfolio

Type

Square sections

Application

Oil & Gas/fracking

Component weight

on request

Grades

1.4542, 1.4313, 1.6932

Type

Square sections/shouldered

Application

Machine components for the energy sector

Component weight

on request

Grades

1.4903, 1.4901, 1.6368, 1.7380

Type

Square sections

Application

Mining/Chemicals and petrochemicals industry

Component weight

on request

Grades

1.4404, 1.4313, 1.4021, 1.4571, 1.4301, 1.4057, 1.4541, 1.4462

Type

Discs

Application

Machine components for the energy sector

Component weight

on request

Grades

1.4313

Type

Customised machined open-die forgings

Application

Component weight

Grades

Your contact for components for special applications

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Andreas Bruntsch

Sales Director Open Die Forgings & Machining

Further processing possibilities

Heat treatment

Soft-annealing

Quenching and tempering (horizontal and vertical)

Spray quenching

Mechanical processing options

Milling

Turning

Millturning

Drilling

Grinding

Werkstoffprüfungen

Automated ultrasonic testing

Manual / automatic Ultasonic testing

Magnetic crack detection

Determination of chemical analysis

Compression, tensile, Charpy V-notch tests

Microstructure testing

Hardness tests (HV, HB, HRc)

Dimensional inspection

Hot true-running test

What you can expect

Raw material recycling

We use almost 100% scrap in our low-CO2-emission steel production for our open-die forged products, thereby enabling closed loops

Wide range

Various geometries and weights for our open-die forgings

Great variety

We can offer a wide range of material grades for our open-die forgings

Our innovations

Find out more about the future of steel and the exciting developments that are shaping our world.