Tool steel

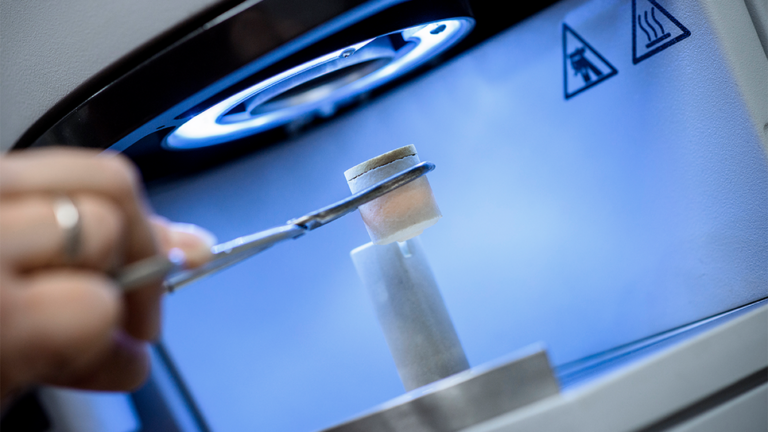

Our tool steel is used for the production of tools, molds and standard parts, for example in the areas of aluminum die casting or plastic injection molding.

Schmiedewerke Gröditz is an integrated steel plant operating two powerful open-die forging presses (24 MN and 60 MN) and three advanced ESU facilities. We primarily supply global stockholding distributors, supported by our dedicated service centers located in Burg (Germany, GWB) and Istanbul (Turkey, GCE).

Our product range focuses on high-quality plastic mould steels, die steels, hot-work steels for die casting, and stainless steels, available in annealed or heat-treated condition. We offer both conventionally produced and ESR-remelted grades.

Gröditz specializes in large-scale forgings, including die holders, mould frames, and tooling materials for giga-casting applications. Flat materials are available starting from 250 mm thickness, and round materials from 300 mm diameter.

Specifications

Tool steel

Plastic Mould Steels

High-performance solutions for demanding applications For decades, we have been a reliable partner to the tool and mould-making industry as well as to the plastics processing sector. We produce standard and special steel grades tailored specifically for plastic injection moulding, compression moulding, and plastic extrusion applications.

Our special steel grades meet the exact requirements of the industry:

- High-gloss polishing: XPM VICTORY ESU, SWG 2343 VICTORY ESU

- Textured surface etching: XPM, 738HH

- Fibre-reinforced plastics: GPM58 VICTORY ESR

- Chemically aggressive plastics: SWG 2316 VICTORY ESU, SWG 2316mod VICTORY ESU, SWG 2083 VICTORY ESU, SWG 2083mod VICTORY ESU, CRMHP VICTORY ESU, OPTI N+

Our materials ensure superior precision, durability, and outstanding surface quality.

Your contact

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Stefan Urbaniak

Sales Director Tool Steel

Hot Work Steels

Exceptional performance and reliability at high temperatures

Our hot work steels meet the highest standards of toughness, hot strength, wear resistance, and tempering resistance. Engineered for extreme operating conditions, they consistently deliver outstanding performance across diverse applications:

High- and Low-Pressure Die Casting

Excellent toughness and heat resistance for long-lasting tools

(SWG 2343 VICTORY ESU, SWG EX1 VICTORY ESU, SWG EX8 VICTORY ESU)

Die Forging (Dies and Die Holders)

Optimal balance of wear resistance and toughness

(SWG 2714, SWG 2714mod, SWG 2367, SWG 2343, SWG EX6)

Press Hardening

Superior wear resistance and tempering resistance under maximum stress conditions

(SWG EX6 VICTORY ESU, GPM58 VICTORY ESU, SWG 2344 VICTORY ESU)

Extrusion

Exceptional hot strength for stable and durable extrusion tooling

(SWG 2343, SWG 2344)

Benefit from maximum tool life, economic efficiency, and outstanding process reliability.

Your contact

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Stefan Urbaniak

Sales Director Tool Steel

Cold Work Steels

Precision and wear resistance for demanding processes. Our cold work steels deliver exceptional precision and outstanding wear resistance for cutting, stamping, embossing, bending, and other cold-forming applications. The optimized properties of our special steels ensure long tool life and consistently reliable performance.

Typical steel grades include:

- SWG 2379

- SWG 2379 ESU

- SWG 2358

- SWG 2363

Rely on our materials for excellent tooling performance, cost-efficiency, and superior process reliability.

Your contact

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Stefan Urbaniak

Sales Director Tool Steel

Further processing possibilities

Heat treatment

Tempering

Special annealing processes

Mechanical processing options

Turning

Milling

Service and Consulting

Competent application consulting

Supply Chain

Warehouse and milling/sawing center in Burg near Magdeburg (Germany)

Own warehouse locations in Turkey / Germany

Authorized contract dealers in all relevant markets

What you can expect

Raw material recycling

We use almost 100% scrap in steel production, enabling closed loops

Low emissions

We use low-CO2 steel produced via the electric arc furnace route

Related products

Customized Tool Steel

Forged stainless steel

Our innovations

Find out more about the future of steel and the exciting developments that are shaping our world.