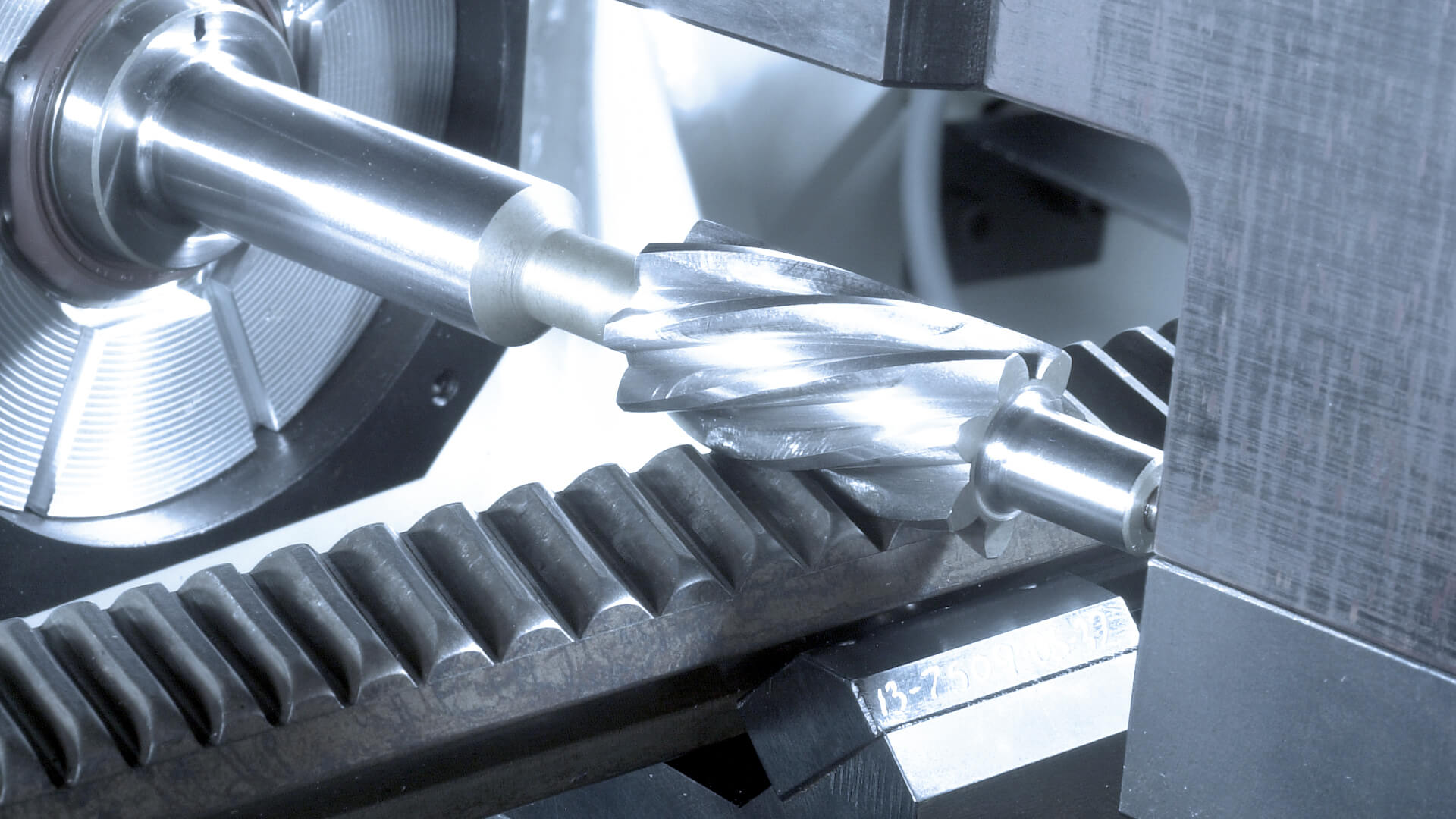

High-tech precision

GMH Gruppe produces high-quality steering racks for leading automotive-industry manufacturers, including VW, TESLA, BOSCH, JTEKT, NEXTEER, INA, MANDO, MOBIS, ZF/TRW. These steering racks are noted for maximum precision and maximum dimensional accuracy.

Automotive steering systems demand special levels of precision and dimensional accuracy. Here, Metallverarbeitung Ostalb (MVO) supplies excellent products in the form of ready-to-install steering racks. What makes them special, in addition to outstanding precision, is their variable toothing geometry for all transmission ratios and their versatile rack cross-section geometries.

Patented process

The necessary maximum of accuracy in our steering racks demands not only decades of know-how in production and materials but also special processes and high-performance machines. Here, using our latest warm-forging cell, with its forging capacity of 1.5 million components per year, and our patented Bishop warm forging process, we achieve results that precisely match specifications and customers’ wishes.

The benefits of the Bishop warm forging process:

- Excellent precision for specific toothing qualification trials

- Both variable and constant toothing systems

- D, U and V steering-rack cross-sections

- For both quenching-and-tempering and non-heat-treated steels.

Versatile solutions, constant precision

Precision is guaranteed by our patented Bishop warm forging process in many ways. Particularly worthy of note is the ultra-accurate forming of the toothing to meet specifications. Our warm-forging cell can be adjusted with maximum accuracy for materials properties in the toothing. Special requirements for the toothing can also be produced with maximum precision.

9 years of know-how in the production of components for automotive steering systems (status: early 2021)

Many potentials

For more than nine years now, we have been using this process for the production of high-quality components for automotive steering systems. We can produce both constant and variable toothing systems, V cross-sections and also D and U cross-section types. In addition, we also produce in both quenching-and-tempering and non-heat-treated steels.

Reliable partners

Not only automotive steering systems necessitate special accuracy in our daily work. Many years of cooperation with suppliers and automotive-industry manufacturers demands maximum reliability from us. Our in-house further development of the technologies used, capability for efficient completion of major projects and dependable adherence to production schedules assure our customers that they get high-tech combined with guaranteed precision and reliability from us every time.