Precisely to the customer's requirements, 0.2 mm measuring accuracy

Ultra-accurate special profiles

Mannstaedt special profiles are matched precisely to the geometry and grade of steel the customer requires. A specially developed high-accuracy measuring technology for hot-rolled steel profiles makes an important contribution to this.

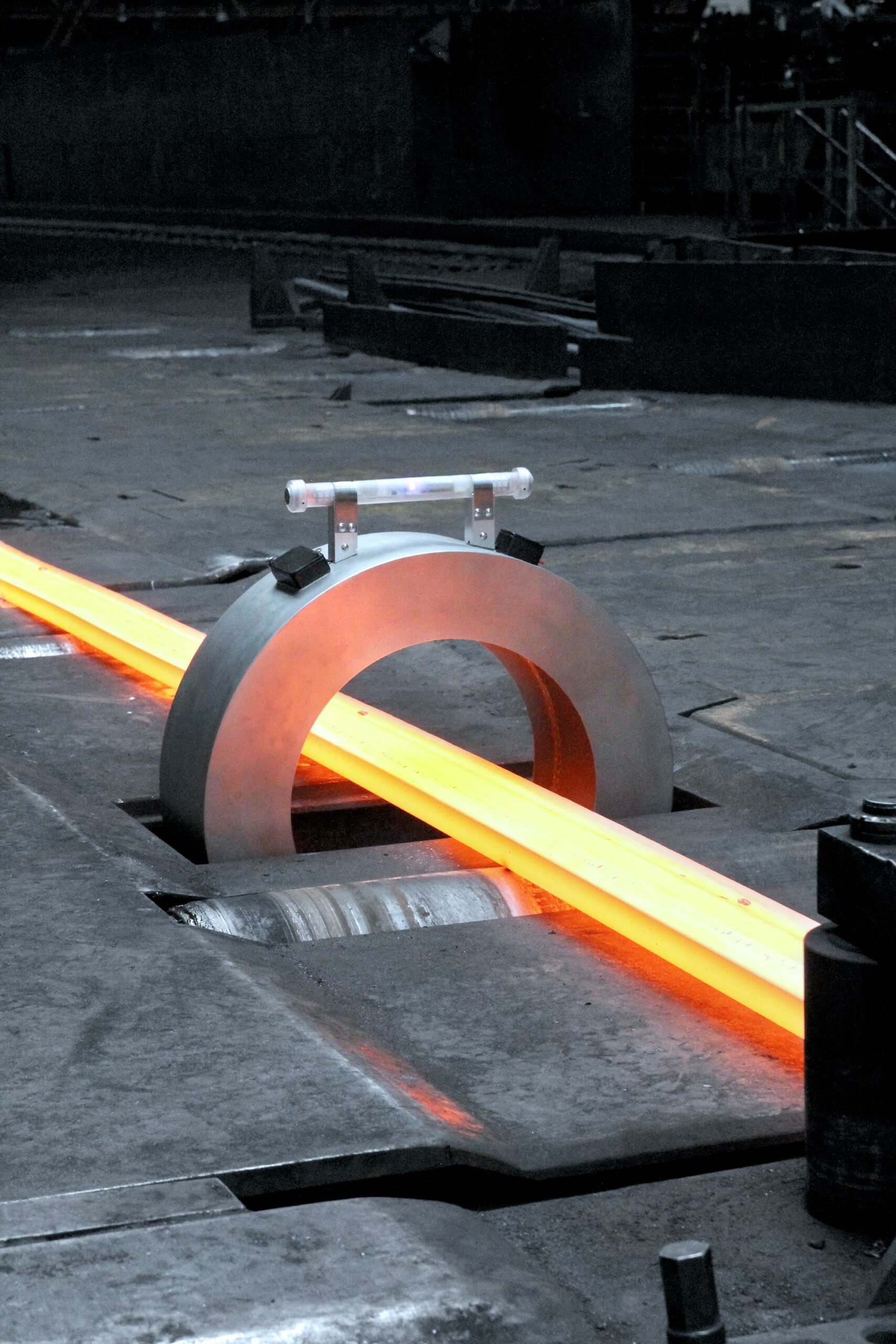

Mannstaedt special profiles are individually made products that precisely meet specifications and the customer’s wishes. They assure not only special materials properties, bar and piece length, straightness and perfect surface quality, but also maximum contour accuracy. Mannstaedt achieves ultra-accurate results using the mobile Calipri Hot laser-based system for measurement of the contour of incandescent profile bars: the measured data attains an accuracy of 0.2 mm.

Applications for our high-precision laser-based measurements

- Roll-pass design of new rolled profiles

- Elimination of samples otherwise needed between the rolling stands

- Product changes in the rolling line

- Development and optimisation of profiles

Efficient, high-precision measurement

In order to achieve ultra-accurate results for our customers, Mannstaedt inspects the incandescent profile geometries during the rolling process at up to 1000° C in a few seconds and with an accuracy of measurement of 0.2 mm. Thanks to the high efficiency of this measuring system, this form of quality inspection means not only ultra-high accuracy but also significant savings on effort and time.

Versatile applications

This measuring method, employing mobile laser-based systems, is used during various process operations. It replaces, for example, the taking of sample measurements between the rolling stands. In addition, it is also applied at product changes on the rolling line and for the development and optimisation of both new and already proven profiles.

0,2 millimetre accuracy

We measure the individual forming operations for our special profiles during the ongoing rolling process with a measuring accuracy of 0.2 mm.

Developed using Mannstaedt’s own expertise

Calipri Hot, the flexible portable laser-based system for measurement of the contour of incandescent bars, has been jointly developed between NextSENSE and Mannstaedt. In line with an idea provided by Franz-Dieter Philipp, the know-how of the rolling-mill crew, in particular, was incorporated, with the support of Christian Trappmann and Martin Schütt (both members of the Mannstaedt Production department), into the development work. Prototype tests performed on a small-scale rolling line readied the system for series use.

Unique product range

Precision in quality inspection is an important factor in Mannstaedt’s globally unique range of products. This is additionally noted for a large selection of material grades and the diversity of its possible applications. Products of 15 to 180 kg/m can be made on rolling lines with a capacity of 250,000 t/a in widths of a maximum of 400 mm and maximum bar lengths of 24 m (heavy sector) and of 2 to 35 kg/m with maximum widths of 180 mm and bar lengths up to a maximum of 18 m.