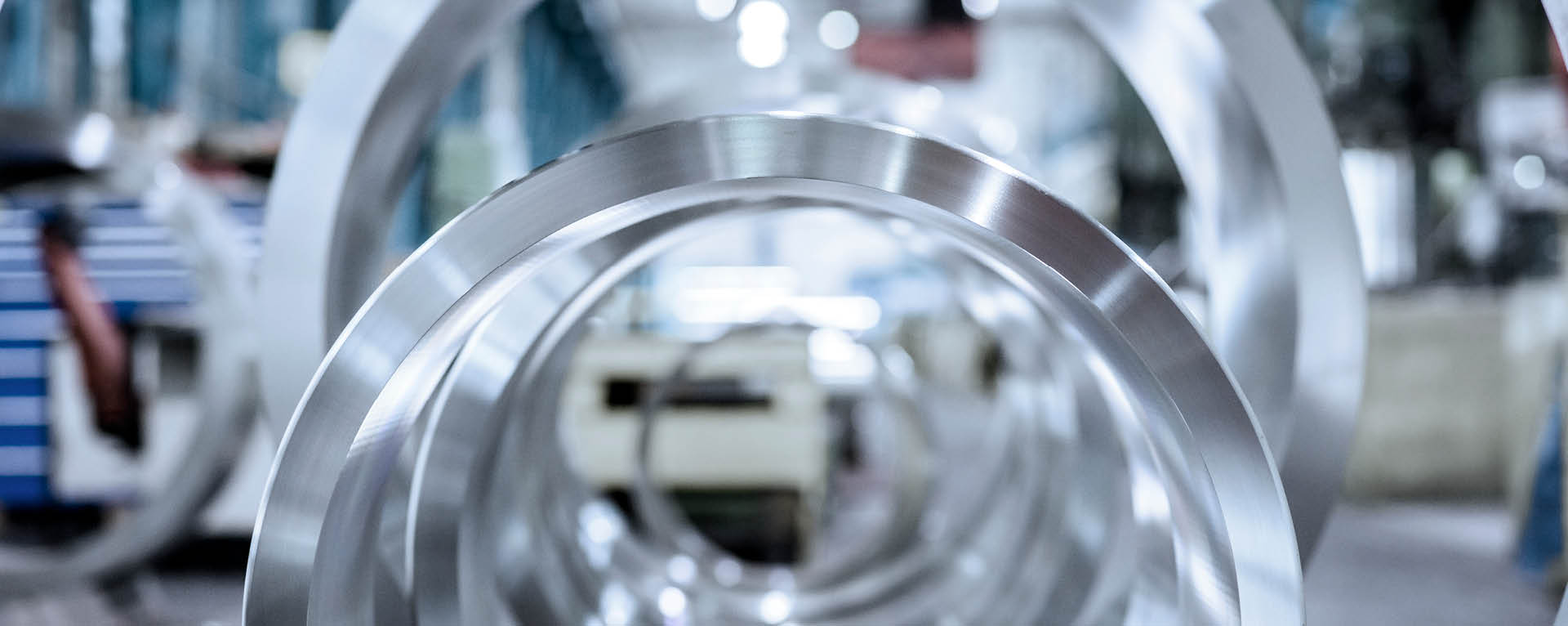

Retaining rings

We have been manufacturing cap rings for turbo generators for over 100 years and are constantly developing them further. This has made us the world market leader in this segment.

To produce our cap rings, the steel is first remelted in ESR systems and then shaped into the correct form in open-die forging. The rings are then pre-turned, heat-treated, cold expanded, stress-relieved, turned and tested.

We manufacture the following dimensions:

Austenite

We use the austenitic steel P900 (material number/DIN code: 1.3816, ASTM A 289, Class C, X8CrMnN18-18) developed by us to ensure that our cap rings can withstand the enormous centrifugal forces.

Samples from our Portfolio

Material

P900

Material no.

1.3816

Name

X8CrMnN18-18

Your contact for rotor retaining rings

We manufacture all our products to customer specifications. So what are your specifications?

Please feel free to contact us. Together we will find your perfectly customized solution.

Jörg Schulze

Sales Director Retaining Rings & HNS

What you can expect

Circular economy

We use almost 100% scrap in steel production, thereby enabling closed loops

Low CO2 production

use of 100% material from the electric arc furnace

Highly resilient steel

Highly resilient steel with high yield strength, very good cold and hot forming properties, low thermal expansion, non-magnetizability and resistance to stress corrosion cracking